- Mumbai, Maharashtra

- GST NO. : 27AAFCV2943K1ZZ

- View Mobile Number

| Business Type | Manufacturer, Exporter, Supplier |

| Driven Type | Electric |

| Condition | New |

| Automatic Grade | Automatic |

| Click to view more | |

Preferred Buyer From

| Location | Worldwide |

Product Details

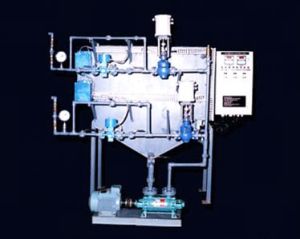

VEL Cooler water spray system comprises of complete set of skid mounted pumping & valve train system along with spray nozzles & relevant accessories. All necessary instruments, control valves etc are provided. All closed loop controls, sequence of operation, alarms & Safety interlocks are provided. The system may be interfaced to your existing PLC/DCS or may be provided with a standalone control panel.

DESIGN CRITERIA

The purpose or application, dimensions of the Grate Cooler, the height of the clinker bed, the overall gas flow, the gas temperature, the clinker temperature profile, number of nozzles needed and the height at which the lances are to fixed in the cooler compartment, the degree of cooling required put together determines the type of is spray system to be used,that is:

Compressed air atomized water spray system

Spillback water spray system

Fogjet / Multicone water spray system

Flatjet water spray system

Application

In Cement Industries, VEL Grate Cooler Water Spray System is used for cooling the vent gas for any of these purposes:

To increase the efficiency of ESP by reducing fugitive dust emission.

To reduce the power consumption of the vent outlet fan.

To maintain a slightly more negative pressure at vent outlet thus contributing in reducing fugitive emission.

To reduce the temperature so that the upstream conveying equipments could be designed for lower temperatures thus reducing the capital cost.

To cool the clinker directly so that the inlet temperature to cement mill is within controllable limits.

To control the depth of the clinker bed both to avoid grate burn-out due to low bed depth, and to avoid stalling the cooler fans due to excessive bed depth.

To limit fluctuations in the secondary air temperature as this can upset the kiln temperature profile and adversely affect clinker quality.

Principle Of Operation

In VEL Grate Cooler Water Spray System, the temperature of the stream of gas / clinker is cooled in three stages:

Heating of the injected liquid to the boiling point temperature corresponding to the system pressure.

Conversion of part of the liquid into a gaseous state by evaporation of the liquid.

Superheating of the evaporated liquid.

We can also provide Grate Cooler Water Spray System especially for Direct Cooling of Clinker bed. This is normally required when the cooler is operated above its designed capacity.

We design, manufacture, supply to achieve your ultimate goal.